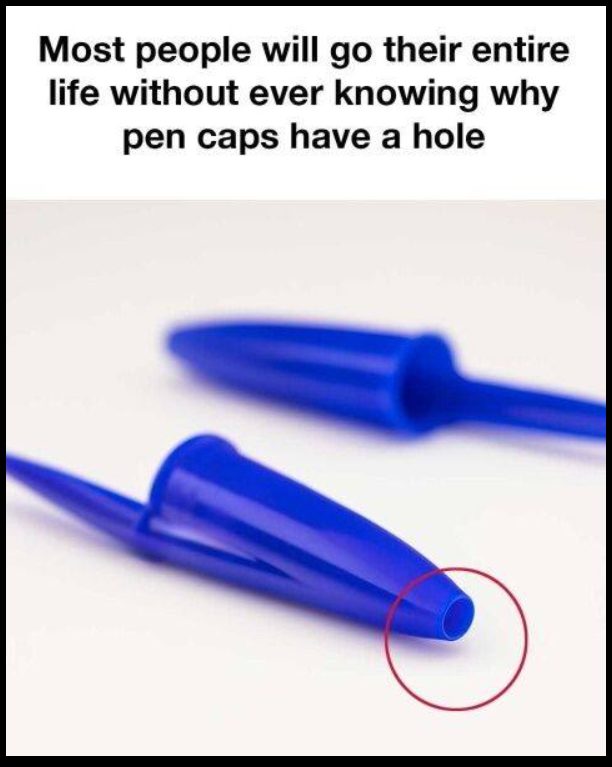

Most people never give a second thought to the tiny hole in a pen cap, but it turns out this small feature is a result of smart, thoughtful engineering rather than random design. Pen caps aren’t just made to protect the tip of your pen from damage or drying out; they are carefully crafted with tiny holes for several important reasons that benefit users more than they realize.

First and foremost, safety plays a major role. One of the key reasons manufacturers add a hole in the cap is to help prevent choking. If someone, especially a young child, accidentally swallows the cap, the hole allows a small amount of air to pass through, providing a chance to breathe while waiting for medical help. This simple yet life-saving design was introduced in response to growing concerns about choking hazards, and it has since become a standard across many pen brands around the world. Beyond safety, the hole also plays a crucial role in how the pen itself functions.

Changes in air pressure, like those experienced during air travel or even with shifts in weather and altitude, can cause problems for a sealed pen. Without a way to balance internal and external pressure, a pen might leak or the ink flow could become inconsistent. That tiny hole acts as a pressure equalizer, allowing the pen to maintain steady ink flow and prevent messy leaks, making writing smoother and more reliable no matter where you are. So next time your pen works perfectly at 30,000 feet in the air, you can thank that little hole in the cap. But the benefits of this clever design don’t stop there.

From a manufacturing standpoint, adding a hole is also about efficiency and cost savings. When companies produce millions of pens each year, even the smallest reduction in material use can result in significant savings. By leaving a hole in the cap, manufacturers use less plastic, which not only reduces production costs but also speeds up the cooling and setting process during molding. Faster production times mean more pens made in less time, lowering overall costs and making pens more affordable for consumers without sacrificing quality. It’s a win-win situation that benefits both businesses and customers alike. Another interesting aspect is how some brands have embraced the hole as a part of their signature design. In a competitive market where standing out matters, incorporating the hole into the visual identity of the product helps make certain pens instantly recognizable.

Companies like BIC have successfully turned their pen designs into icons, with the hole in the cap serving as an understated but memorable feature that people associate with reliability and everyday usefulness. It’s a brilliant example of how functionality and branding can work hand-in-hand. When you consider all the reasons behind the design, it becomes clear that the hole in a pen cap is anything but random. It’s a carefully considered element that enhances safety, improves performance, cuts manufacturing costs, and even adds to brand identity, all without being flashy or drawing attention to itself. This small, easily overlooked feature is a reminder of how thoughtful engineering often hides in plain sight, quietly making everyday life better and safer without demanding recognition. So the next time you absentmindedly fiddle with a pen cap or chew on it during a long meeting, remember that the tiny hole you’re feeling with your fingers is the product of smart, purposeful design. It’s proof that sometimes the most brilliant ideas are the ones you barely notice, seamlessly blending into daily life while serving multiple important functions. Appreciating these small details can change how you look at the ordinary objects all around you. That tiny hole isn’t just there for looks; it represents a thoughtful balance of practicality, safety, efficiency, and style that has quietly stood the test of time. Next time you use a pen, you’ll know the real story behind that tiny hole and understand just how much thought went into making something as simple as a pen cap truly extraordinary.